Laser-acoustic testing method for production lines

The optical microphone from Xarion Laser Acoustics was combined with an ultrasound-generating laser, making it possible to detect defects in components that cannot be seen from the outside, such as cracks, holes or poor connections.

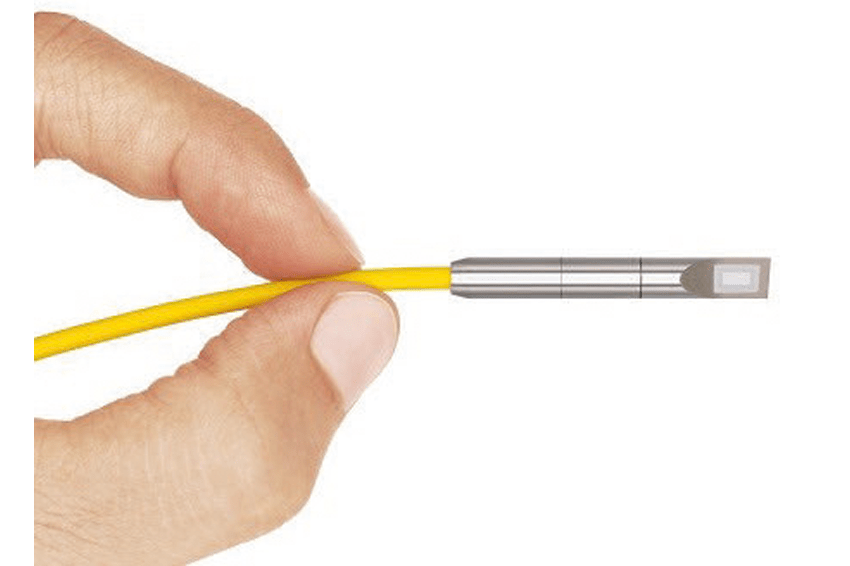

The optical microphone does not have an oscillator. In its purely optical process, the sound changes the wavelength of a laser beam, which is reflected back and forth between two small mirrors.

This also changes the brightness of the decoupled light, which is measured without the detour via a mechanical vibration. In this way, the optical microphone achieves a detectable frequency interval that is at least twenty times larger than that of a conventional ultrasonic sensor. In addition, contact with the examinee can be dispensed with.