The winners of the inspect award 2020

19.11.2019 -

The field of applicants was strong, so there was little room between the nominees. But ultimately the readers of the inspect made a choice and each chose a winner from the categories "Vision" and "Automation + Control". The winners will be briefly described below. A more detailed coverage follows in the upcoming issues for each winner.

The winners of the category Automation + Control

First place: Keyence Germany

3D coordinate measuring machine: XM-1200

The XM series is a mobile 3D coordinate measuring machine. The measurement is made via a hand-held probe, which communicates with a special camera via infrared signal. The camera can determine the exact coordinates via the infrared measuring points on the button. The wide visual image and the free handling of the probe allow high flexibility in 3D measurements. The all-in-one design makes it possible to include the device in the process. The XM can be used on a mobile trolley in production, on a desk or in a measuring room. An air-conditioned measuring room is not necessary. On the software side, the device uses augmented reality, dramatically increasing its user-friendliness.

Second place: GOM

Metrology Computer Tomography: GOM CT

In order to achieve a high degree of detail in component digitization, the components of the GOM CT were perfectly matched: A high-contrast 3k X-ray detector generates a pixel grid of 3008 x 2512 pixels and thus lays the foundation for the high-precision detection of the component. A 5-axis kinematics with integrated centering table makes it easy for the user to optimally position the component in the measuring volume so that the measurement is always carried out in the best possible resolution. Practical: Within the measuring field with a diameter of 240 mm and a height of 400 mm, several objects can be measured simultaneously, which further reduces throughput times.

Third Place: Ametek, Creaform Division

Portable 3D scanner: Handyscan Black

The Handyscan Black is a hand-held 3D scanner that does not require a tripod or external tracking device to operate. It fits into a small transport case, so it can be transported anywhere without problems and is ready for use in less than two minutes. This stand-alone device has multiple blue laser crosses and automatic mesh generation that allows faster workflow from setup to scan to file. The scanner is versatile and can measure all types of parts, regardless of size, material, complexity and surface finish - from small gears to complete vehicles. It achieves an accuracy of 0.025 mm.

The winners of the category Vision

First place: Vision Engineering

Digital stereoscopic 3D display: Deep Reality Viewer

It is the world's first true digital stereo 3D display with integrated microscope module. The Deep Reality Viewer (DRV) offers the user, in addition to numerous ergonomic advantages, the first image detail on a 3D widescreen digital 3D display while ensuring full interaction with other users or remote users in remote locations (using a second DRV system) ) or complementary analyzers. DRV has the particular advantage of multi-site companies being able to provide real-time Full HD 3D stereo images to multiple users in multiple locations simultaneously. This is becoming increasingly valuable for feedback / communication along the entire supply chain.

Second Place: Imago Technologies

Linux-based smart camera with event-based sensor

Linux-based smart camera with new event-based sensor, dual-core ARM Cortex-A15 CPU, accelerator, Gbit / s Ethernet and digital IO. The new camera sensor responds pixel-individually only to changes in movement and thereby massively reduces redundant data, e.g. from the background. Each pixel is able to transmit motion changes down to the kHz range. Fastest motion analyzes and classifications are thus possible. Due to the high data reduction, the smart camera already has enough computing power to run an entire application on the integrated Linux computer. Motion information is also delivered between otherwise common fixed sampling rates of high-speed cameras. Existing high-speed applications are replaced by just a smart camera.

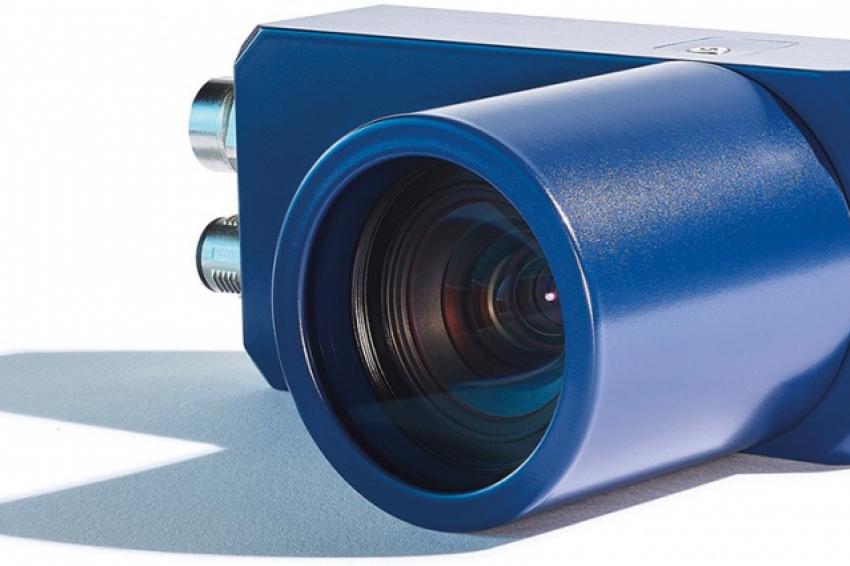

Third place: Edmund Optics

Lenses for APS-C sensors: CA series

With the CA series, Edmund Optics developed a lens series specifically for the newly emerging APS-C sensor format with 28 mm diagonal. Particularly noteworthy is the TFL mount used, which can be considered with a M35 x 0.75 thread at 17,526 mm flange size as a big brother of established for smaller sensors C-mounts. Compared with the already established lens connections, the TFL mount offers the following advantages: First of all, the TFL mount is significantly more stable, especially in comparison to the widespread F mount due to the screw cap, and is thus better suited for industrial applications. Furthermore, the TFL mount allows the design of more compact lenses compared to the larger F-mount or M42 lenses, which are also used for full-format sensors with 43.3 mm diagonal. In addition, the TFL mount is standardized by the Japan Industrial Imaging Association (JIIA).

Contact

Keyence Deutschland GmbH

Siemensstr. 1

63263 Neu Isenburg

Germany

+49 6102 3689-0

+49 6102 3689-100

Vision Engineering Ltd.

The Freeman Building, Galileo Drive

Send, Woking, Surrey GU23 7ER

+44 1483 248 300

Imago Technologies GmbH

Straßheimer Str. 45

61169 Friedberg

Germany

+49 6031 684 26 11

+49 6031 684 26 12

Ametek GmbH - Division Creaform Deutschland

Meisenweg 37

70771 Leinfelden-Echterdingen

Germany

+49 711 185 680 30

+49 711 185 680 99